Advanced laser measuring systems have transformed chassis repair services, offering unprecedented accuracy, speed, and non-destructive assessments for vehicle restoration and collision repairs. These tools enable auto body shops to capture precise 3D measurements, enhancing the safety and performance of vehicles through meticulous repairs that meet original specifications. By replacing traditional methods, laser systems streamline workflows, providing customers with more accurate, efficient, and cost-effective chassis repair services. When selecting a system, consider specific needs for resolution, range, data processing, and integration to satisfy both intricate restoration and routine maintenance tasks.

Chassis Repair Service Specialists Use Laser Measuring Systems

In today’s digital era, chassis repair services are undergoing a significant transformation. The evolution of laser measuring systems has emerged as a game-changer, revolutionizing how specialists approach precision and efficiency in their work. This article explores the benefits of integrating laser technology into chassis repairs, from enhancing accuracy to streamlining workflows. We’ll guide you through choosing the right laser measuring system for your service, ensuring optimal performance and results.

- The Evolution of Chassis Repair: Why Laser Measuring Systems Are a Game-Changer

- How Laser Measuring Systems Enhance Precision and Efficiency in Chassis Repairs

- Choosing the Right Laser Measuring System for Your Chassis Repair Service

The Evolution of Chassis Repair: Why Laser Measuring Systems Are a Game-Changer

The evolution of chassis repair techniques has seen a significant shift towards precision and efficiency, driven by advanced technologies. Laser measuring systems have emerged as a game-changer in the field, revolutionizing how chassis repair service specialists approach their work. These innovative tools offer unprecedented accuracy and speed, transforming what was once a labor-intensive process into a streamlined procedure.

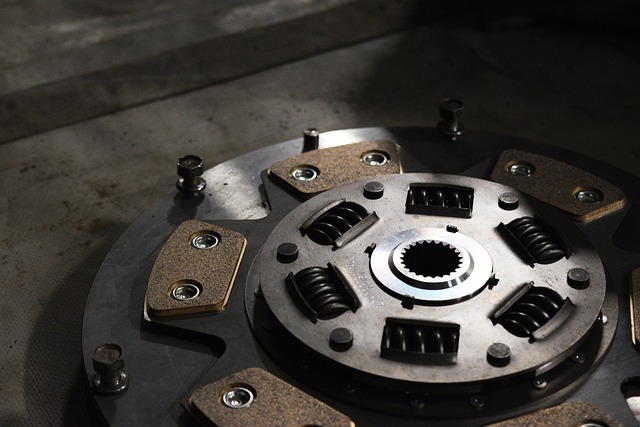

In the realm of vehicle restoration and auto collision repair, laser measuring systems provide a non-destructive way to assess and rectify damage. Auto body shops can now capture precise 3D measurements of chassis components, ensuring meticulous repairs that match original specifications. This level of detail is crucial for achieving flawless outcomes in auto body repair, ultimately enhancing the safety and performance of vehicles.

How Laser Measuring Systems Enhance Precision and Efficiency in Chassis Repairs

Laser Measuring Systems have transformed chassis repair processes in auto repair shops and car repair services, offering unprecedented precision and efficiency gains. These advanced tools utilize laser technology to capture precise measurements of vehicle components, allowing specialists to conduct accurate assessments and make minutiae adjustments during repairs. This level of detail is crucial for ensuring that every part aligns perfectly, especially when dealing with intricate chassis structures.

By replacing traditional measuring methods, auto repair services can streamline their workflows significantly. Laser systems provide quick and reliable data, enabling technicians to compare it against original specifications and identify discrepancies swiftly. This real-time feedback empowers them to make informed decisions, enhancing the overall quality of chassis repairs. As a result, customers benefit from more accurate, efficient, and cost-effective auto repair shop services.

Choosing the Right Laser Measuring System for Your Chassis Repair Service

When selecting a laser measuring system for your chassis repair service, consider the specific needs and challenges of your work. Different systems offer varying levels of precision, range, and speed, so choosing the right one is key to efficient repairs. For instance, if your service primarily deals with intricate car body shop restoration and dent removal, opt for a system with high-resolution sensors and advanced algorithms that can accurately measure complex shapes and curves.

Conversely, if your chassis repair service focuses on structural integrity checks and alignment, a system with longer range and robust data processing capabilities may be more suitable. Ensure the laser measuring system you choose integrates seamlessly with your existing tools and software, allowing for smooth workflow transitions. This not only streamlines your processes but also enhances the accuracy of your repairs, ultimately ensuring customer satisfaction in both car restoration and routine maintenance tasks.

Laser measuring systems have revolutionized the landscape of chassis repair services, offering unparalleled precision and efficiency. By embracing this innovative technology, specialists can ensure meticulous measurements, streamline repair processes, and deliver superior quality work. With the right system selected based on specific needs, chassis repair businesses can stay ahead in a competitive market, catering to clients who demand top-tier, precise repairs.