Laser measuring systems revolutionize chassis repair service by offering unprecedented precision and efficiency. These tools enable auto body specialists to accurately measure vehicle dimensions, crucial for restoring intricate components to original specifications. By streamlining the repair process and enhancing quality, laser technology also facilitates tailored tire services, boosting vehicle safety and performance post-repair.

Chassis Repair Service specialists are revolutionizing the industry with their adoption of laser measuring systems. This cutting-edge technology offers unparalleled precision in evaluating and repairing vehicle frames, ensuring structural integrity and safety. In this article, we explore the evolution of laser technology in chassis repair, highlighting its numerous advantages for achieving exacting standards. We also delve into how specialists utilize these systems to efficiently restore damaged chassis, offering a deeper look at their expert approach.

- Chassis Repair: The Evolution of Laser Technology

- Advantages of Laser Measuring Systems for Precision Repairs

- Efficient Chassis Restoration: A Specialist's Approach

Chassis Repair: The Evolution of Laser Technology

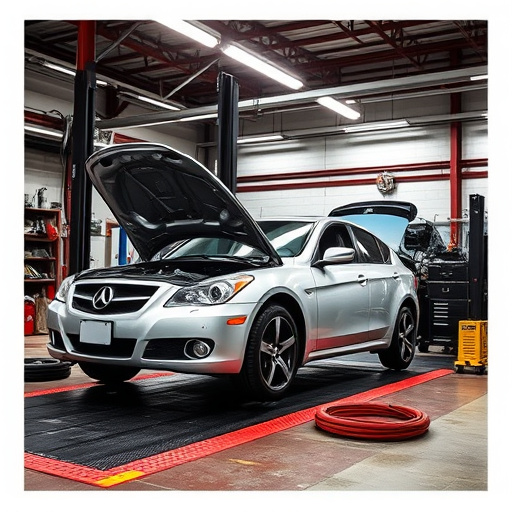

The evolution of chassis repair has seen a significant shift towards precision and efficiency with the introduction of laser measuring systems. These cutting-edge tools are revolutionizing how chassis repair service specialists work, enabling them to achieve unparalleled accuracy in their auto body repair processes. Unlike traditional methods that relied heavily on manual measurements and guesswork, laser technology offers a non-invasive and highly precise way to capture vehicle dimensions. This advancement is particularly crucial in the intricate world of automotive collision repair, where even minor discrepancies can impact the overall quality of the restoration.

Laser measuring systems provide chassis repair service specialists with digital data, allowing them to quickly and accurately assess damage, plan repairs, and ensure proper alignment. Not only does this streamline the repair process, but it also enhances the overall quality of auto body repair. With these systems, technicians can precisely measure and compare various vehicle components, including panels, frames, and suspension systems, ensuring every part is restored to its original specifications. Moreover, the integration of laser technology in chassis repair has opened up new possibilities for tire services, enabling specialists to offer more tailored solutions and better ensure vehicle safety and performance post-repair.

Advantages of Laser Measuring Systems for Precision Repairs

Laser measuring systems have revolutionized chassis repair service specialists’ capabilities, offering unprecedented precision and efficiency. These advanced tools provide accurate measurements, enabling experts to identify even the slightest imbalances or deviations in vehicle structures. This level of detail is crucial for intricate car collision repair and ensuring that every component is restored to its original specifications.

Unlike traditional measurement methods, laser systems provide non-contact, quick, and repeatable data capture. This technology ensures consistent results, reduces human error, and saves time, all of which are significant advantages for collision repair shops. Moreover, the precision afforded by these systems translates into superior car paint services, as well, allowing for seamless repairs that seamlessly integrate with the vehicle’s original design.

Efficient Chassis Restoration: A Specialist's Approach

In the realm of chassis repair service, specialists employ cutting-edge technology like laser measuring systems to ensure efficient and accurate restoration. These advanced tools play a pivotal role in the hands of seasoned professionals, allowing them to navigate complex vehicle body shop challenges with precision. By capturing precise measurements of damaged components, laser measuring systems enable specialists to create detailed digital blueprints for collision repair services.

This innovative approach streamlines the entire process, from diagnosing issues to fabricating replacement parts. As a result, clients benefit from faster turnaround times and superior quality work. With laser measuring systems, chassis repair service specialists can confidently tackle even the most intricate restoration projects, ensuring every vehicle returns to its original state or even surpasses it in terms of performance and aesthetics.

Chassis repair service specialists are leveraging laser measuring systems to achieve unprecedented precision in their work. By embracing this innovative technology, they can efficiently restore damaged chassis components with a level of accuracy that was once unattainable. The advantages of laser systems—including faster measurements, reduced human error, and enhanced visual aids—have made them an indispensable tool in the modern chassis repair service industry.